Selected projects

| Each project is unique We have several years' development and construction experience, including the following areas:

Your wishes are our challenges! Below a small selection of customised construction solutions for our customers: |

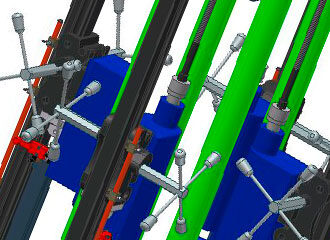

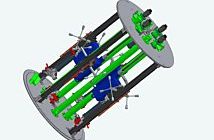

> Drilling device in tunnels

Customer segment: Tunnel construction

page up

Customer segment: Tunnel construction

Development and manufacturing of various drilling devices for the assembly of supporting structures in tunnels and on ceilings. Features:

|

page up

> Hoisting platform with 340 t bearing load

Customer segment: Shipping

page up

Customer segment: Shipping

Manufacturing, delivery and assembly of the hoisting gear (2x1700 kN) to lift ships out of water. Features:

|

page up

> Hoist for rostrums

Customer segment: Culture

page up

Customer segment: Culture

Construction and delivery of a rostrum for 110 persons which can simply be pulled up to the ceiling after use. This enables, for example, use of the room as a cinema or a showroom. Features:

|

page up

> Special winches for the construction of a suspension bridge in Bangkok

Customer segment: Bridge construction

page up

Customer segment: Bridge construction

Construction and delivery of two draw winches for drawing the stay ropes (cords) for the Rama 8 bridge in Bangkok. Features:

|

page up

> Development of a new generation of cable pull machines

Customer segment: Cable laying technology

page up

Customer segment: Cable laying technology

Construction of a new 3 t capstan pulling machine with a wide range of application. The newly developed machine provides the following advantages among others:

|

page up

> Construction of a compressor for a railway traction vehicle

Customer segment: Railway

page up

Customer segment: Railway

Installation of a standard compressor from the company Atlas Copco in a chassis and integration in the straight crossfall of a vehicle from the TMR (Transport de Martigny et Régions). The system offers the following advantages:

|

page up

> Installation of protective earthing in door systems for the Hong Kong underground

Customer segment: Closure technology

page up

Customer segment: Closure technology

| A new earthing system was developed in direct collaboration with the customer, guaranteeing the reliable earthing of railway platform doors. The challenges to be mastered included:

|

page up